Bodyfence

Application GuideFEATURES

BODYFENCE is a clear, self-adhesive film featuring an enhanced surface sliding, developed especially to protect automobile bodies. Thanks to its outstanding impact-proof properties, it protects your car body against chipping caused by gravel, insects, car doors bump, car

wash brushes, etc. It also provides an excellent vandalism protection.

PREPARING YOUR APPLICATION SURFACE

Your BODYFENCE film can be applied to any vehicle body as long as the target surface is clean, smooth, non-porous and free from any traces of oil, grease, wax, silicone or other contaminants. To avoid unexpected outcomes, always assume that every substrate is dirty

and needs to be cleaned.

Do not forget to carry out a preliminary trial on a small surface to check if the substrate remains undamaged.

For further technical information on the BODYFENCE film, please refer to the technical data sheet available on our website at www.hexis-graphics.com.

Discover Lasting Protection

REQUIRED EQUIPMENT

- 1-litre PULVERISAT vaporiser

- 11-litre PULVITRE vaporiser

- Water + pH-neutral soap

- STEAMERSC1 STEAM CLEANER

- HEXISGEL application liquid

- MARJO squeegee

- BLUESQUEEG squeegee

- YELSQUEEG squeegee

- BLAKSQUEEG squeegee (soft)

- CUTOLFA30 30° blade cutter

- LAMOLFA30 refill

- “System 1-2-3” cleaning liquid:

- 1-Remover

- 2-Pre-Cleaner

- 3-Final Cleaner

- ProTech® SHAMPCAR car shampoo

- Soft cloth

STORE YOUR FILMS UNDER APPROPRIATE CONDITIONS

Keep the films away from any major source of heat (radiators and heaters, direct exposure to sunlight, etc.): the best temperature ranges from 15 °C to 25 °C (59 °F to 77 °F) with relative humidity of 50%.

Store your films in their original packaging, in a dry environment. The rolls are wrapped in sealed polyethylene bags and are maintained in their cardboard packaging by plastic suspension caps to prevent the windings from being crushed by their own weight.

Always store the rolls in an upright position.

Recommendations

Optimal adherence of the BODYFENCE film is obtained after 24 hours following application.

BODYFENCE is usually used on the vehicle body areas the most exposed to aggression (bumper, bonnet, doors, etc.), however, it may also be used on the entire car surface!

After cutting the necessary film length for the wrapping project, the remaining film must be stored on its original core (do not cut the rolls into several lengths, do not repackage the product); the roll must be closed immediately and properly after use (tape or roll-collars), without exerting pressure on the film, in order to preserve all its qualities.

PRELIMINARY TEST OF THE APPLICATION SURFACES

Before proceeding with any application, the installer must first inspect the substrate and the paint to which the film will be applied.

The installer and the client are responsible for the suitability assessment of the target surface to be covered.

Preliminary inspection of the substrate

Any fresh new paint must have dried for at least 7 days at 25 °C (77 °F) to outgas completely. An outgassing test must be carried out before applying the film.

Any old, powdery or flaky paint must be sanded and renewed before application and must undergo a tear-off test.

Tear-off test

Using a TESA® 7476 adhesive tape, or the like, apply to a surface of 2.5 cm x 5 cm (1 in. x 2 in.) plus some overhang material for easier removal. Fold and promptly tear off perpendicularly to the substrate surface. No traces should remain on the ripped off adhesive tape. Repeat this process in several places.

On request, HEXIS can provide you with a Tesa® adhesive tape in 2.5 cm x 5 cm (1 in. x 2 in.) size.

Outgassing test

Use a square piece of around 15 cm x 15 cm (6 in. x 6 in.) of self-adhesive polyester or of the film to be applied. Wait for 24 hours or 2 hours at 65 °C (149 °F). The appearance of bubbles indicates that the substrate has insufficiently outgassed. Therefore, this process should be repeated after a couple of days; or else the procedure described below should be carried out.

Outgassing procedure with flame treatment:

(Polycarbonate, translucent or diffusing methacrylate, expanded PVC, etc.)

This method consists of changing the surface tension of a substrate by swiping it with the flame of a gas burner. Using the flame’s blue tip, proceed evenly with fast sweeps horizontally and vertically along the whole substrate surface.

MOVE THE FLAME IN SWIPING MOTIONS ON THE SUBSTRATE (RISK OF DESTROYING THE SUBSTRATE IF A FIXED POINT IS HEATED MORE THAN A SECOND).

The film must be applied right after that treatment as this light surface treatment disappears after a few minutes.

HEXIS are not liable for any bubbles caused by outgassing.

Cleaning

Cleaning of the substrate is required before performing the application. It should always be assumed that the substrate is contaminated with dirt. Some residues or contaminants may not be visible; however, they may impact the adherence of the film.

Before using any cleaning liquids or chemicals, please refer to the technical data sheets and safety data sheets available for download on our website at www.hexis-graphics.com.

Clean and soiled surface appearance

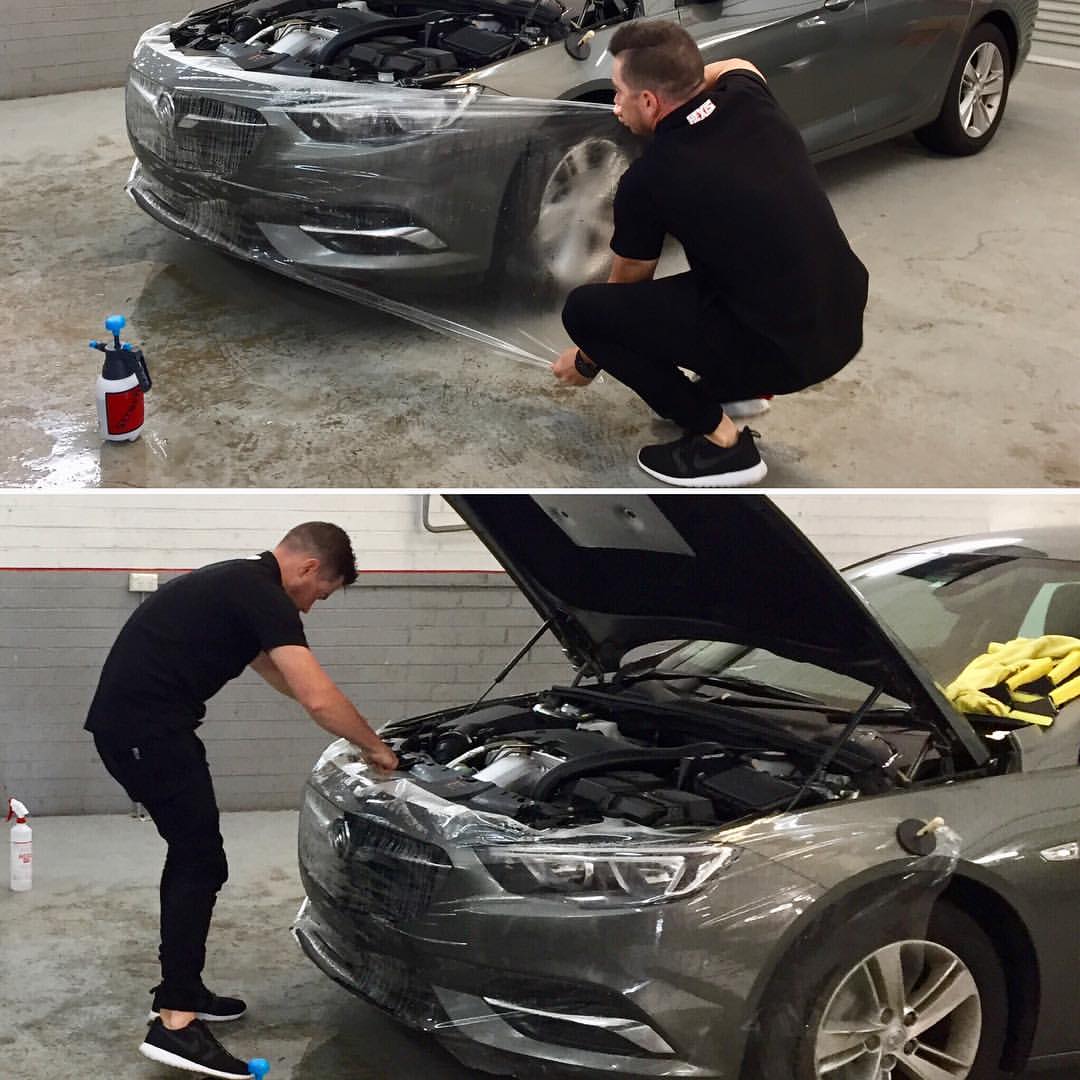

For vehicle wraps, it is advised to wash the vehicle with the SHAMPCAR vehicle body shampoo, then use the PRE CLEANER (product no. 2).

› Spray it onto the surface.

› Let it work for a few minutes, then wipe it dry with a clean cloth.

› Carry out a final cleaning using the FINAL CLEANER (product no. 3).

Heavily soiled surface appearance

For vehicle wraps, it is advised to wash the vehicle with the SHAMPCAR vehicle body shampoo, then use the ADHESIVE REMOVER (product no. 1).

Work in a ventilated area. Wear protective goggles.

Prior to treatment, run a compatibility test on a small, inconspicuous area of the substrate to be treated. Indeed, certain plastic materials might be damaged by the ADHESIVE REMOVER (product no. 1).

› Spray onto the dirty surface and spread out using a dry cloth.

› Then wait for a few minutes. Spray the ADHESIVE REMOVER (product no. 1) again, then wipe it dry with a clean cloth or squeegee.

› When the substrate is clean and dry, clean again with the PRE CLEANER (product no. 2), then finish with the FINAL CLEANER (product no. 3) (as explained below).

Cleaning

Application of the Bodyfence Film

The recommended minimum application temperature is +10°C (+50°F). Preferably, apply at a temperature ranging from +15°C to +35°C (from +59°F to +95°F).

BODYFENCE films must be applied according to the «wet» method, using either soapy water or our ready-to-use HEXISGEL product (for high-deformation surfaces).

› For an application with soapy water, prepare the 1-litre PULVERISAT vaporiser using 1 ml to 4 ml of pH-neutral soap, supplemented with water. This mixture allows to be easily removed.

› Measure the parts to be covered. Cut the BODYFENCE . while leaving a margin of at least 10 cm (4 in.) around the surface to be covered in order to stretch it during application, and avoid any finger marks.

(FIG. 01)

› Carefully separate the liner from the BODYFENCE. (FIG. 02)

› Spray the vehicle body to be protected as well as the adhesive-coated side of theBODYFENCE with the HEXISGEL or soapy liquid (PULVERISAT) (FIG. 03). This will enable a better positioning of the product on the vehicle.

› Firmly stretch the BODYFENCE and position it (adhesive-coated side on the body) in order to wrap the structure. (FIG. 04)

For an optimal wrapping of a concave or convex surface, it may be necessary to soften the film using the STEAMERSC1 steam cleaner.

› Apply the film using one of these squeegees (MARJO, YELSQUEEG, BLUESQUEEG or BLAKSQUEEG) upon size and deformation level needed for the covered surface. Each of these scrapers has a hardness ranging from soft to hard.

› To ensure that the squeegee glides easily, spray the HEXISGEL or soapy liquid (PULVERISAT) onto the BODYFENCE film. Then apply it, holding the squeegee at 45°. Press firmly to adhere the film to the surface and remove the application liquid. (FIG. 05)

› After all removal of the BODYFENCE for adjusting or positioning, spray the film and vehicle body before any reapplication.

› Considering the different existing paint qualities, it may be necessary to activate the adhesive strength by spraying the very concave and/or convex shapes with HEXISGEL.

› Once the BODYFENCE film is applied, cut as indicated in the following paragraphs:

Straight cut with overlap

To avoid scratching the paint, the cutter blade must always be parallel to the vehicle body.

› Use a cutter with a new blade.

› For carrying out the cutting, the cutter blade must be placed against the edge of the adjacent section. During cutting, make sure you always follow this edge by positioning the cutter towards the outside. (FIG. 06)

› After cutting, 2 to 3 mm (1 to 11⁄2 in.) of the film should overlap the edge of the covered vehicle body.

› If there are no adjoining sections, cut the film surplus leaving a 2- to 3-mm (1- to 11⁄2-in.) film overlap. (FIG. 07)

› Remove any excess film.

› To finish, run the squeegee over the cut. Incline the squeegee towards the thinner edge (FIG. 08). Firmly apply over the edges, round parts and neighboring or opposed areas.

› Always cut the angles of the BODYFENCE film in rounded sections in order to ensure optimum adhesion of the cut film edges.

Cut without overlap

This method is used for a cut along a seal or any trim that cannot be disassembled.

› Use a cutter with a new blade.

› Trace with your finger the contours of the area. Lift the vinyl of the adjacent part and drag it into the hollow using a squeegee so as to mark the seal edge.

› For cutting, the cutter blade must be placed in flat position on the squeegee.

› The squeegee + cutter blade must be parallel to the body and perpendicular to the seal.

› Make the squeegee/cutter blade compound slide over the body to carry out the cutting by always maintaining this blade orientation.

› Remove any excess vinyl.

› Cut the angles of the BODYFENCE film in rounded sections in order to ensure optimum adhesion of the cut film edges.

› Finish off by firmly running the squeegee over the cut.

Finishing

› Place absorbent paper on the MARJO squeegee. Apply pressure to the cut edges to remove as much as humidity as possible. (FIG. 09)

› Firmly apply the film with the squeegee to the edges, rounded sections and adjacent or opposite faces of the body. (FIG. 10)

› If wrinkles appear at the edge trim, press them with your finger for approximately 30 seconds. (FIG. 11)

CLEANING AND MAINTENANCE OF THE BODYFENCE FILM

For optimum maintenance of your BODYFENCE film, HEXIS suggest to use their range of ProTech® cleaning agents specially designed for the total wrap.

The BODYFENCE film can be cleaned in any conventional automatic car wash, using cleaning products and detergents used for professional maintenance of vehicles and advertising equipment.

Nevertheless, for the use of high-pressure cleaners, respect the following procedure: apply medium water pressure at a minimum distance of 50 cm (20 in.) and a maximum water temperature of 35°C (95°F).

Caution: However, the film should not be cleaned within the first 48 hours following its application as this can affect the adhesive strength that may result in the film peeling off.

Caution: Solvents and corrosive detergents must not be used.

HEXIS are not liable for any adhesive films cleaned with the unspecified additives from cleaning stations.

Car washes: The additive products and the condition of the rotating brushes may impair the adhesive strength of the films. It is commonly admitted that after 10 car washes, the polyurethane paint becomes streaked; therefore, and in the same way, we are not accountable for these mechanical effects that may affect the film appearance.

HEXIS tip: Always carry out a test on a small area before cleaning the entire surface to be covered.

CLEANING AND MAINTENANCE OF THE BODYFENCE FILM

Removal Procedure

The BODYFENCE film features a special adhesive designed to facilitate removal.

› Lift the corner gently with the cutter without damaging the substrate.

› Subsequently proceed, by heating small areas, to peel off the film gently.

› The film should form an angle of 70° to 80° relative to the substrate surface to reduce the risk of leaving any adhesive on the substrate or tearing off the film.

An angle more or less wide or acute will cause the film to break more easily.

› Continue to peel off the film gently until it is completely removed while keeping a watchful eye on the heat applied, on the pulling angle of the film, and the pulling speed.

› If any adhesive remains on the substrate, take a cloth soaked with our ADHESIVE REMOVER (product no. 1) and rub the surface until all traces disappear.